Whilst researching the Story of the Beachy Head Lighthouse book, one of the aspects of that research was the original construction of the lighthouse using granite blocks which came from the De Lank quarry, near St. Brewards in Bodmin in Cornwall.

The original granite blocks

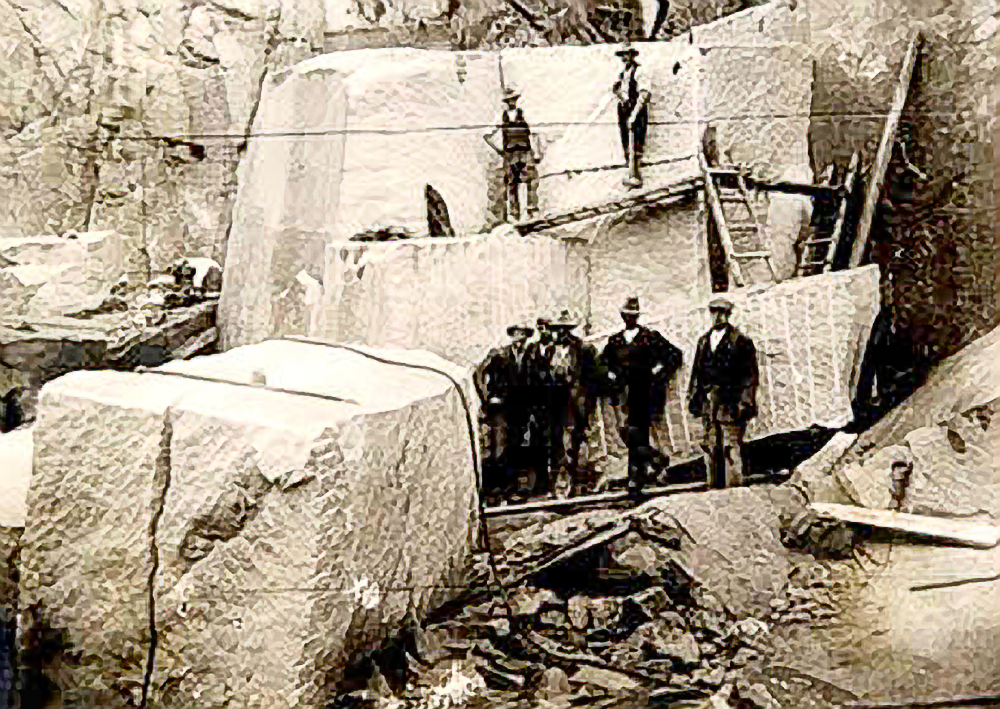

The picture I associate with the original quarry and the men who produced the granite blocks is this one. This photo is from the late 1800s/early 1900s.

What is really incredible is that these men had a design template to work with and they fashioned every single granite block by hand to make the lighthouse fit together like a giant 3D jigsaw puzzle.

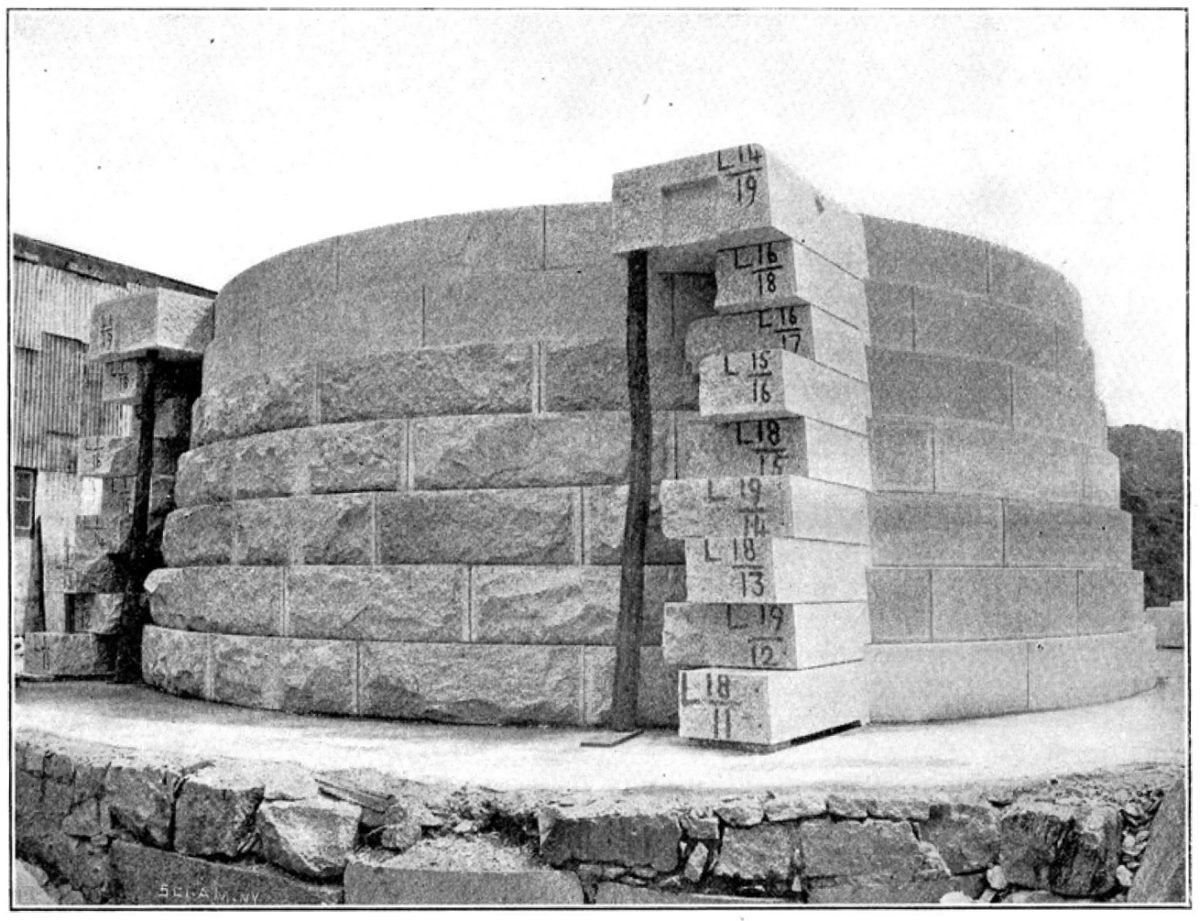

Every stone was prepared and numbered so that its position in the construction of the lighthouse could be identified. This number denoted the course number and position in the tower.

The granite blocks were then transported by railway wagons, in order, from Cornwall, to East Sussex where they were unloaded at Eastbourne Station. They continued up to Beachy Head and into position by track up to the clifftop overlooking the construction site on the beach below.

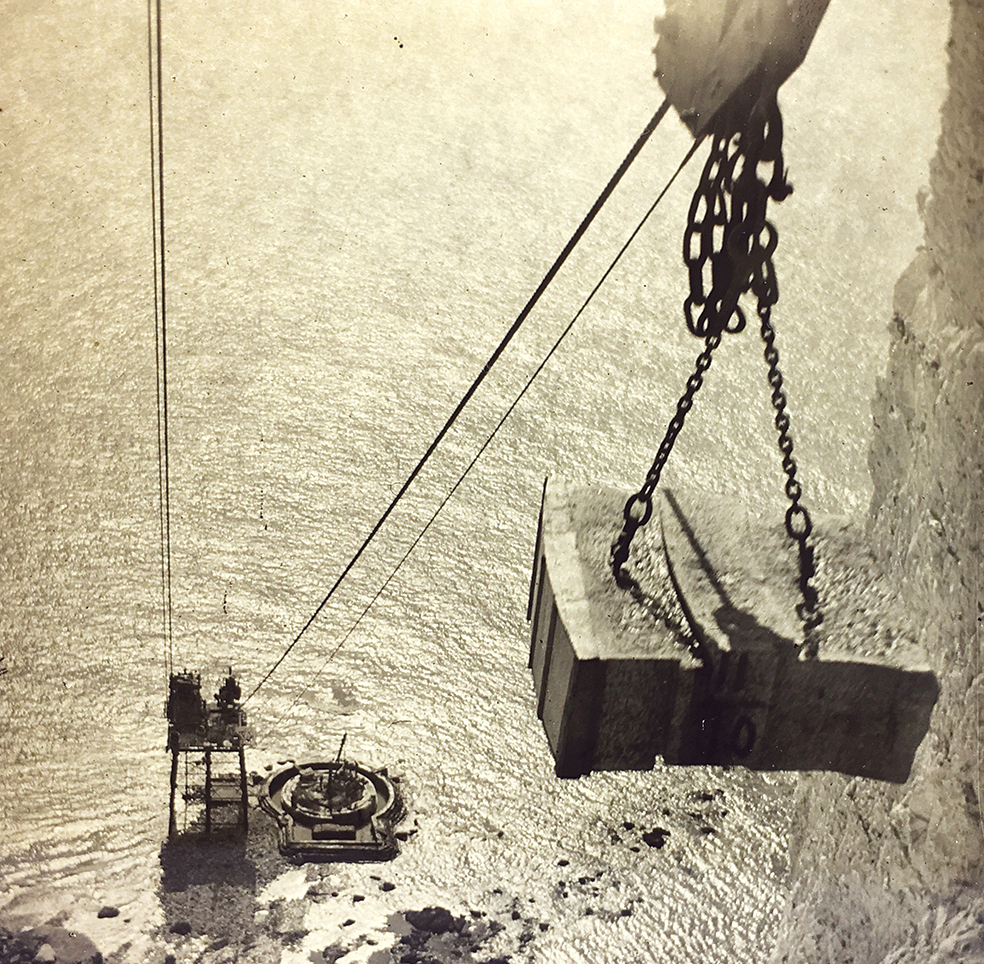

You can clearly see how the granite blocks are all lined up and numbered ready to go. These would be carried by the cable rope-way system down to the landing platform at the construction site anchored to the sea bed..

When the block arrived at the landing platform, the workmen would prepare the stone to be lifted by crane into position on the lighthouse tower.

The crane would then lower the block to the team below who would position the granite block in place in the tower. Each block located corresponding to the course number and block number as per the original plan.

Most blocks were 22 inches thick (55.9cm) and fashioned with a dovetail so that each block sat snugly against its partner. The blocks weighed between one and two tons each. There are 26 courses of interlocking granite blocks. The tower is approximately 141 feet (43m) tall. The total weight of granite used was 3,660 tons.

I have previously had the opportunity to visit the lighthouse and be able to see and touch the granite blocks up close – now you get an idea why, over time, I have become so fascinated with the raw material and this amazing stone that the lighthouse is constructed from.

A very special invitation

I had always hoped that one day I might be able to visit the very place where the granite blocks came from and, on Thursday 15th August 2025 – that dream came true for me.

The De Lank quarry is an operational quarry business and is private property. They do not allow visits but I was given special permission due to my involvement with the lighthouse. I am really grateful for the De Lank quarry in making my visit a possibility.

The De Lank quarry is near St. Brewards in Bodmin in Cornwall. The quarry has been operational for over 200 years. You can find out more about his amazing place on their own website www.delankquarry.co.uk

What an entrance

The quarry has changed over the years and at some point in its history they blasted their way through the rock to create a new entrance. And what an entrance this is – it is like a man-made gorge. It is really imposing and very impressive.

A quarry nowadays is quite a different place to what they used to be like. I can imagine 125 years ago that this place would have been buzzing, a real hive of activity to supply stone for construction worldwide. And – the fact is, it still is, but just not in the same quantity as it was years ago.

The De Lank quarry has supplied granite to an impressive list of buildings – including the US Embassy in London, London Bridge, New Scotland Yard and even Buckingham Palace. They also have their own skilled team of stonemasons and impressive production machinery. I guess like a lot of things these days, the bulk supply of building materials comes from other sources, but if you want high quality granite stone and skilled preparation and stone-masonry, then you come to a specialist like the De Lank quarry in Cornwall.

The De Lank quarry was visited by King Charles in 2018. The quarry supply granite and stonework to the Duchy of Cornwall – an impressive badge of honour!

I was kitted out with boots, hi-vis vest and hard hat and I was very privileged to be given a tour of the quarry.

This is the current stone face they are working from. I had expected them to use explosives, just like the ‘old days’, but instead they use a thermal lance, huge cutting disks or block cutters.

I guess I had imagined lots of noise and chaos but it is a really slick and very organised operation with very specific processes happening in separate places.

I was given the opportunity to see how stones are cut – using huge 3m cutting disks. I saw how stones are prepared using polishing equipment and even burning using a high temperate flame to achieve a rougher textured surface. I then saw the stonemasons hard at work with their hammers and chisels carefully and delicately fashioning the stone.

I was then able to see the different areas where they store, grade and sort stone ready for different purposes, including some to be taken away and pulverised for granite stone chippings.

I am very grateful for the opportunity and I can’t thank the De Lank quarry enough for this once in a life time experience.

You can find out more about the De Lank quarry on their website.

Another Special Photo

There is another photo which is very special which is this one of De Lank Quarry, St Brewards, Bodmin, Cornwall and dated 24th September 1907.

In this photo you can see the quarry works and various buildings, most of which are now gone. There is a railway track coming in from the bottom left hand corner. We’re looking from the opposite side of the quarry towards the entrance. The entrance would be towards the top middle of the picture.

I wanted to be able to see how the quarry had changed in over 118 years from a similar vantage point.

There are public footpaths that run around the quarry, so I walked up one of the paths to get to the other side.

It was a narrow, steep and very overgrown path. I was almost ripped to shreds by brambles and it was evident it was not a particularly well-trodden path. What was also interesting is that it was school holidays and, despite places like Boscastle and Tintagel heaving, out here, in-land, it was very, very quiet.

Once I had reached the top path, I could look back across the top of the quarry and see the entrance ‘gorge’ and part of the quarry – on the right, where I had my picture taken earlier.

I continued walking around the edge of the quarry. It had become very overgrown compared to how it was a hundred years ago. Trying to find a position to take an equivalent photo was quite difficult due to the trees.

But, finally, I was able to get to the approximate position from where the original photo was taken. This is quite a wide angle overlooking the whole quarry.

Another perspective on the quarry

The footpath runs around the entire quarry so I wanted to get a view from the other side. I retraced my steps all the way back to the car park and main entrance and walked the path in the other direction. You get quite a good view down into the quarry where they are currently working the quarry face.

When the photo of me in the hard hat was taken, I was standing on the track in the centre of the image. So we are looking down into the quarry.

At the top of this path there are fantastic views …

… such as this view back over the quarry buildings. This is where the workshops are that do all the stone cutting and where the stonemasons work.

And then there are incredible 360 degree views all around.

What an experience – a truly wonderful day!

Thank you for taking time to read this article.

My pictures used may be reproduced with a credit to @robwassell please.

The image of the numbered blocks at the base of the tower is from the Scientific American journal from 1901.

The construction photos are from a collection of old slides which were purchased by The East Sussex Records Office at the Keep in Brighton. They were able to restore all the original slides which you can see yourself by making an appointment. If you have an interest in the Beachy Head Lighthouse or the construction of lighthouses, I would highly recommend it.